Marine Ropes Guide – Everything you should know

What Rope means to your yacht

The rope on a boat is one of the most important and essential tools. From ancient times in navigation, it was the means that handled all the functions of a ship back then. Today, maritime rope remains one of the most important tools on a boat, serving as:

- Rope for securing the vessel – Mooring or mooring rope or cable.

- Rope for towing.

- Rope for sea rescue.

- Rope for securing objects.

- Rope for hoisting – halyard.

- Rope for sail angle adjustment – sheet.

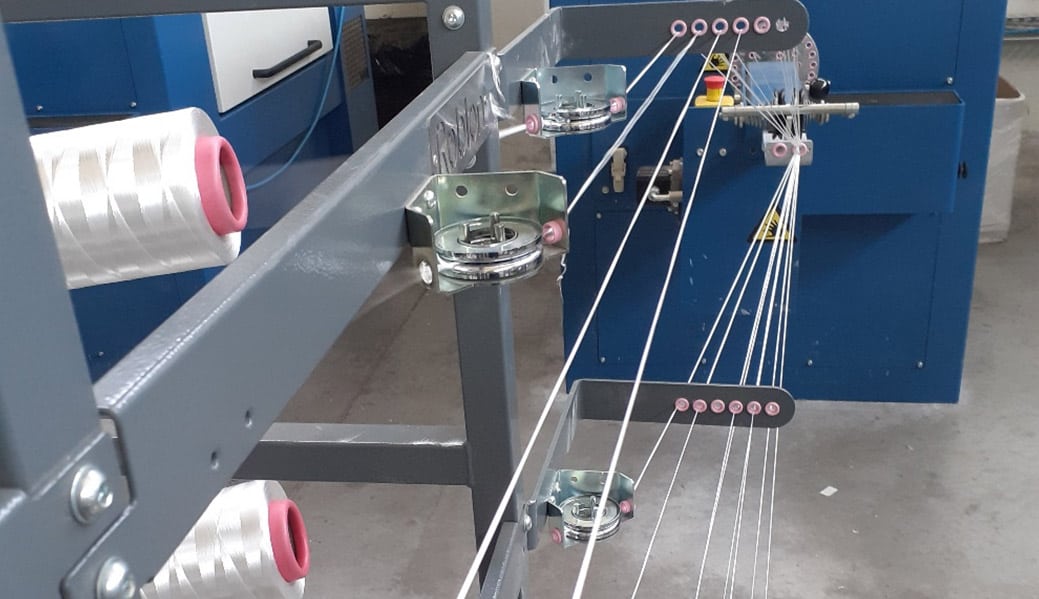

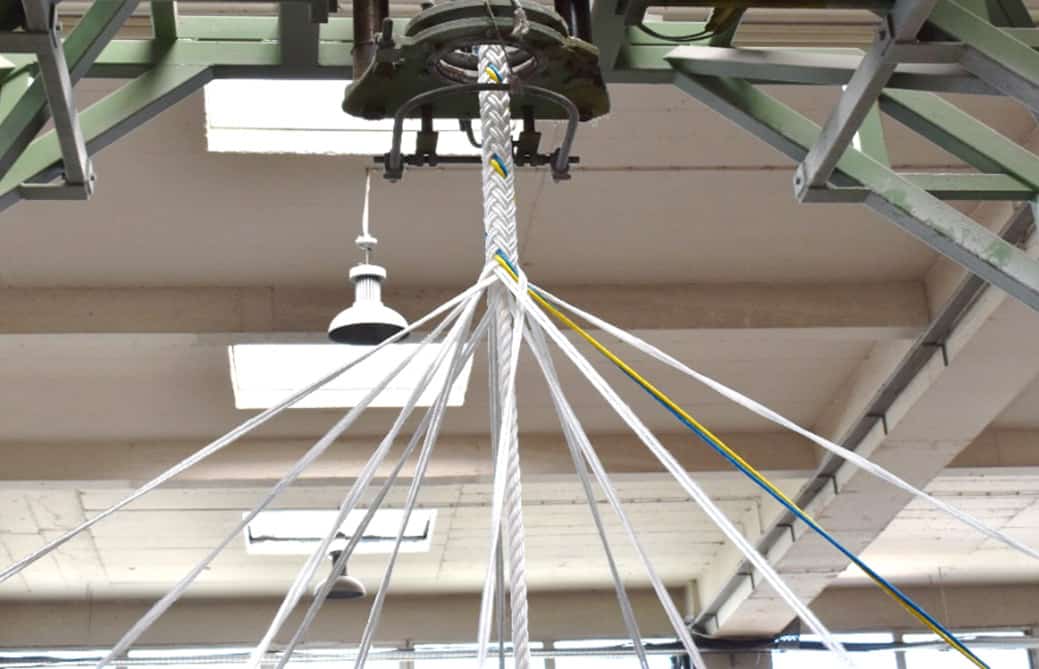

How ropes are made

Before we delve into each category in detail, let’s see how a rope is made and what it consists of in general.

A rope is a complex of fibers that are compressed by twisting or braiding into a long, flexible line. The way the braiding or the number of braids, as well as the material of the fiber, are the distinguishing differences that determine the category, characteristics, and type of use of each rope.

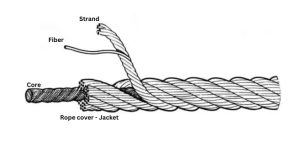

What is a Rope’s Braid

Braids are a complex of fibers braided helically. The more braids, the more friction-resistant the rope is.

Core – Soul of the rope

It is the heart of the rope. It consists of parallel fibers and may be surrounded by a second core of fibers of different material for added strength and rigidity. It determines the elasticity and strength of the rope.

Rope Cover – Jacket

These are the braids that are braided around the core of the rope. The jacket protects the core and is what comes into contact with the hands of the operator or each winch.

Material Fiber and Properties of Ropes

- Natural Fiber (Hemp, Cannabis, Cotton, Manila, etc.)

These are the so-called traditional ropes that were manufactured and used in ancient maritime times. Ropes made from natural fibers shrink when exposed to moisture (water) and tend to fray easily. This is why they are rarely found on modern boats today, as they lack the strength, breaking limit, and elasticity compared to synthetic ropes. However, they can still be used on traditional vessels to add a retro look due to their natural appearance.

- Polyester

Ο πολυεστέρας είναι από τα πιο συνηθισμένα υλικά κατασκευής σχοινιού. Διατηρεί την αντοχή του ακόμα και αν βραχεί, βουλιάζει, δεν ξεφτίζει εύκολα και δεν είναι πολύ ελαστικό. Χαρακτηριστικά που το κάνουν να χρησιμοποιείται για κάθε χρήση, ακόμα και στα Ιστιοπλοϊκά σκάφη για χειρισμό των πανιών.

- Nylon – Polyamide

Nylon ropes are more elastic than polyester but they offer reduced strength when they get wet. They don’t float and are ideal for use as mooring lines, where elasticity is necessary to absorb the load from a boat’s cleats. Nylon ropes tend to be replaced by polyester ropes, due to their wet properties.

- Polypropylene

Polypropylene ropes have low friction resistance and are not resistant to ultraviolet rays. However, their high elasticity, ability to float, and low cost make them ideal for uses such as mooring lines, rescue ropes, and watersports where buoyancy is required.

- Aramid (Technora®)

Aramid (Technora®) presents a combination of high strength, a high modulus (rigidity), and thermal stability. However, it is not very resistant to vibrations. Its use on boats is limited to static loads, such as halyards (sail hoisting ropes).

- HMPE – UHMPE (Dyneema, Spectra)

HMPE (High Modulus Polyethylene) fibers are synthetic fibers known for their exceptional strength. Ropes made from HMPE have become popular for demanding applications, including race sailing. They are known in the yacht market under the brand names Dyneema and Spectra. They have very low elasticity and much higher strength compared to polyester ropes. They are lightweight, buoyant, and resistant to corrosion from seawater, oil, or other chemicals.

HMPE fibers are often used to replace steel cables and are suitable for halyards, sheets, and various high-performance sailing applications.

HMPE fibers are available in various grades: SK38, SK78, and SK99. The higher the number, the lower the creep and the stronger the fiber.

- LCP – Liquid Crystal Polymer

LCP, also known as VECTRAN, is slightly weaker than HMPE fibers but has lower elasticity than HMPE. In the same diameter, Vectran is five times stronger than steel. Due to these properties, Vectran is suitable for applications like sailboat halyards or standing rigging.

Main Rope Categories

Mooring Ropes or Lines, Anchor Lines, Bridles, or Springs

These ropes are used to secure a boat to a dock, pier, or shoreline rocks. Their main characteristic is the elasticity they provide, which varies depending on the type of rope, ranging from 10% to 20%. This elasticity absorbs the force applied to the cleats, protecting them and allowing the boat to swing correctly.

Another key characteristic of mooring lines is buoyancy. When a line floats, it facilitates its transfer through the water since it doesn’t absorb much water and, therefore, doesn’t weigh down as much to sink. Mooring lines that float are recommended for use on large and heavy vessels over 10 meters in length, where a thicker rope is needed and buoyancy is essential. Additionally, floating ropes can be used for water rescue and watersports, such as water skiing.

In this category of mooring ropes, anchor lines are also included. Anchor lines are ropes with weight or non-floating ropes. They are used for permanent anchoring (mooring) since their sinking prevents entanglement with the propellers of passing vessels. They are also used as anchor rode, especially on small boats that can’t accommodate much chain weight.

Halyards

Halyards are ropes used to raise sails, either by hoisting them or by raising crew members to perform maintenance or repairs. They start from the top of the sail, pass through the mast’s sheave, and come down to the lower part of the mast. Their primary characteristic is their minimal elasticity, ranging from 1% to 5%. This minimal elasticity is preferred on racing boats where even millimeters matter in sail trim.

Sheets

Sheets are ropes that control the angle of the sail relative to the wind. They are attached to the edge of the sail and control its trimming. Their main characteristic is their resistance to friction since they pass through blocks, winches, and turning blocks, and minor adjustments are frequent. Additionally, sheets have low elasticity, typically around 5-7%, to absorb gusts and wind shifts.

General-Purpose Ropes

This category includes ropes with varying construction and characteristics that can be used for various purposes. They can be used for decorative purposes and various other uses, and their construction doesn’t significantly affect the outcome. This category may also include ropes made from natural fibers like hemp or cannabis, which are often used in retro or classic boat restorations.

How to Maintain Ropes and Extend Their Lifespan

Whether ropes are made from natural fibers or synthetic materials like polyester, they require maintenance and protection, much like clothing. While cleanliness is a top priority for clothing, ropes have different needs.

- Protect from Sun Exposure: When ropes are not in use, store them in a protected area away from direct sunlight to prevent unnecessary exposure.

- Rinse with Fresh Water: If ropes come into contact with seawater, rinse them thoroughly with clean, fresh water. Seawater leaves behind salt crystals as it evaporates, which can make ropes stiff and promote UV damage.

- Avoid Excessive Knots: Try to avoid excessive knots in ropes, as they can damage the fibers and the rope’s structure.

- Allow to Dry: After rinsing, allow the ropes to dry fully. Avoid storing wet ropes in confined spaces, as this can lead to mildew.

- Annual Cleaning: Consider an annual cleaning with soap and fabric softener in a basin to restore elasticity and color.

By following these maintenance tips, you can help extend the lifespan of your ropes and keep them in good condition for their intended uses.